experience

Established in 1974, PER-FIL® has developed and innovated technology that most of the powder filling machine industry commonly uses today.

Established in 1974, PER-FIL® has developed and innovated technology that most of the powder filling machine industry commonly uses today.

Established in 1974, PER-FIL® developed and innovated technology that most of the industrial powder dispensing equipment industry commonly uses today. Filling powders and granules, as most manufactures of powders know (when done right), can be a challenge.

After thousands of installations, and applications ranging from filling simple free-flowing granules to guacamole and diced tomatoes, to fine smoke-like powders like toner, we have seen almost everything.

In your search for equipment that can handle your unique product, consider the source. Once the machine is installed in your facility, how much confidence do you have that your filler will be able to get the job done with your current product line, as well as, be flexible enough to adapt to future products.

When you run into the inevitable challenge, who will you depend on to get you up and running at high efficiency. You can be confident that PER-FIL will be there to assist you today and in the future.

Whether your installation requires a single stand-alone auger filler or a fully integrated Turnkey Packline, PER-FIL will provide the most suitable filling system for your application.

To know and understand PER-FIL® Industries, you must first know its founder and Chairman, Horst Boellmann. Horst was raised in Germany during World War II. After surviving years of bombing raids, he and his family were forced to leave their home and travel nearly 800 miles to escape from the advancing Russian troops. There was never enough food and no real shelter. These difficult times shaped the man that Horst was to become.

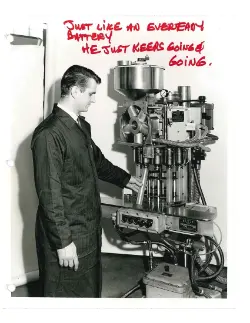

In 1939, when he was only 17 years old, Horst traveled to America with only the clothes on his back and a strong belief that America was the land of opportunity. He quickly got a job as an apprentice Service Technician for Perry Industries, a company that specialized in filling equipment for the pharmaceutical industry. After several years, Horst worked his way up to Plant Manager.

His belief in the “American Dream” remained strong and he was anxious for the day when he could start his own business. The opportunity came when Perry was purchased by The BEMIS Corporation. They decided to discontinue a line of auger filling equipment which they felt was unprofitable. Horst approached the owners about buying this line so that he could start his own business. In 1974, PER-FIL® INDUSTRIES INC. was born! PER-FIL® was named by Horst’s then 8 year old daughter Robyn (who later came to work for the company for many years). The name stands for PERFECT FILLING.

The first few years were very difficult for PER-FIL® with Horst and his partner working 18 hour days. They spent the days selling auger fillers and evenings designing and building. During the early years, PER-FIL® used a shotgun approach to sales; selling equipment to any industry that needed a powder filler. As the company grew, Horst realized that a targeted approach to marketing would be more successful. At Perry, he had some experience servicing equipment for filling toner at Xerox. He believed he could customize the PER-FIL® auger filler to meet the special requirements of this difficult product.

PER-FIL® began developing filling machines and equipment which provided dust-free, accurate dispensing of toner without causing flakes or particles. In 1985, Horst presented PER-FIL’s concept drawings and test results to Xerox. They were so impressed that they cancelled an order with a competitive auger filler manufacturer, to place an order with PER-FIL® for four complete packaging lines. This order changed PER-FIL’s direction and vision. From that point on, PER-FIL® concentrated on designing and manufacturing equipment for the toner industry. During the period from 1985 – 1998, PER-FIL® sales to the toner industry (OEMs and Independents) accounted for more than half of total filling equipment sales.

In 1990, PER-FIL® began working with companies in the Toner Cartridge Recycle Industry. Although still in its infancy, the growth potential for cartridge recycling was obvious to Horst, but he recognized that toner Recyclers had very different needs from the OEMs. Recyclers were remanufacturing a high volume of cartridges, but the cartridges were of many different types. The Recyclers needed a flexible filling system that could fill a variety of different cartridges with very little clean-up or changeover time. Many Recyclers were small operations without in-house maintenance or engineering staff, so a durable, low maintenance filler was required. Additionally, many Recyclers were start-up operations beginning to grow but without a lot of money to invest in capital equipment. These Recyclers required a low-cost filling system and flexible payment options.

Then, one night in 1994, on a flight from Houston to Philadelphia, Horst developed the concept for a small, portable auger filler specifically for the Recycle Industry. This small flexible filling system would use bulk toner in plastic bags. The operator would place the sealed bag inside the machine and it would be cut open inside the machine to eliminate airborne dust. Disassembly and reassembly of the machine would be done by turning hand knobs (rather than using tools) to make cleaning and changeover very simple and very fast. This design featured an electric box that could be easily removed from the filler and returned to the manufacturer for repair. From sketches on an airplane napkin, PER-FIL®’s Model MR-1 MICRO-RECHARGER® came to be the most widely used toner filler system in the Recycle Industry.

In 2001, PER-FIL® completed a building expansion to add more office and manufacturing space. This addition included a state-of-the-art test laboratory for filling equipment demonstrations to the pharmaceutical and bio-tech industries.

In 2002, Horst invented, and PER-FIL® introduced the nano-Filler® and nano-W to meet the needs of Pharmaceutical and Bio-tech companies that needed an accurate powder filler to fill amounts below 1.0 gram.

PER-FIL’s experienced engineering staff stays on the leading edge of filling and control system technology. Extensive application knowledge and experience has resulted in new filler concepts, including Horst's next invention, the patented Multi-Spindle Servo Filler. It was the first powder filler to use multiple augers in a common filler hopper using feedscrew indexing to fill multiple rigid containers each fill cycle. In addition to the MR-1 and Micro-Filler®, this system is regularly copied by other manufactures in the powder filling industry. As Horst says, if you're going to steal copy someone else's equipment, at least steal copy from the best.

multiple rigid containers each fill cycle. In addition to the MR-1 and Micro-Filler®, this system is regularly copied by other manufactures in the powder filling industry. As Horst says, if you're going to steal copy someone else's equipment, at least steal copy from the best.

In 2018 PER-FIL introduced the Entry-level model E-11. It's a full-size machine, with the motor system is based on the reliable Micro-Filler. Per-fect for start-ups and small batch runs. In 2024, PER-FIL® will be celebrating our 50th year in business. A major part of our success is our loyal and dedicated workforce, as well as, our loyal customer base.

In 2024, PER-FIL® will be celebrating our 50th year in business. A major part of our success is our loyal and dedicated workforce, as well as, our loyal customer base.

After 49 years in business, PER-FIL® remains a vibrant, innovative U.S. company with equipment installations in over 90 countries.

PER-FIL’s vision for the future is to continue to design and build innovative filling systems for the world. This equipment combines high quality and performance, with maintenance-free operation.

For 2023 and beyond, PER-FIL®’s goal is to continue to innovate and provide our Customers with the best filling machines and equipment solutions and World-class Customer Service and Support!